novosound develops ultrasonic sensing technology used across commercial and medical sectors. Their core innovation lies in flexible ultrasound sensors that enable non-invasive inspection and monitoring.

As a lean team working across multiple client engagements, they chosen to engage with i4PD as a trusted external partner to help deliver complex product development projects.

Product imagery / video courtesy of novosound

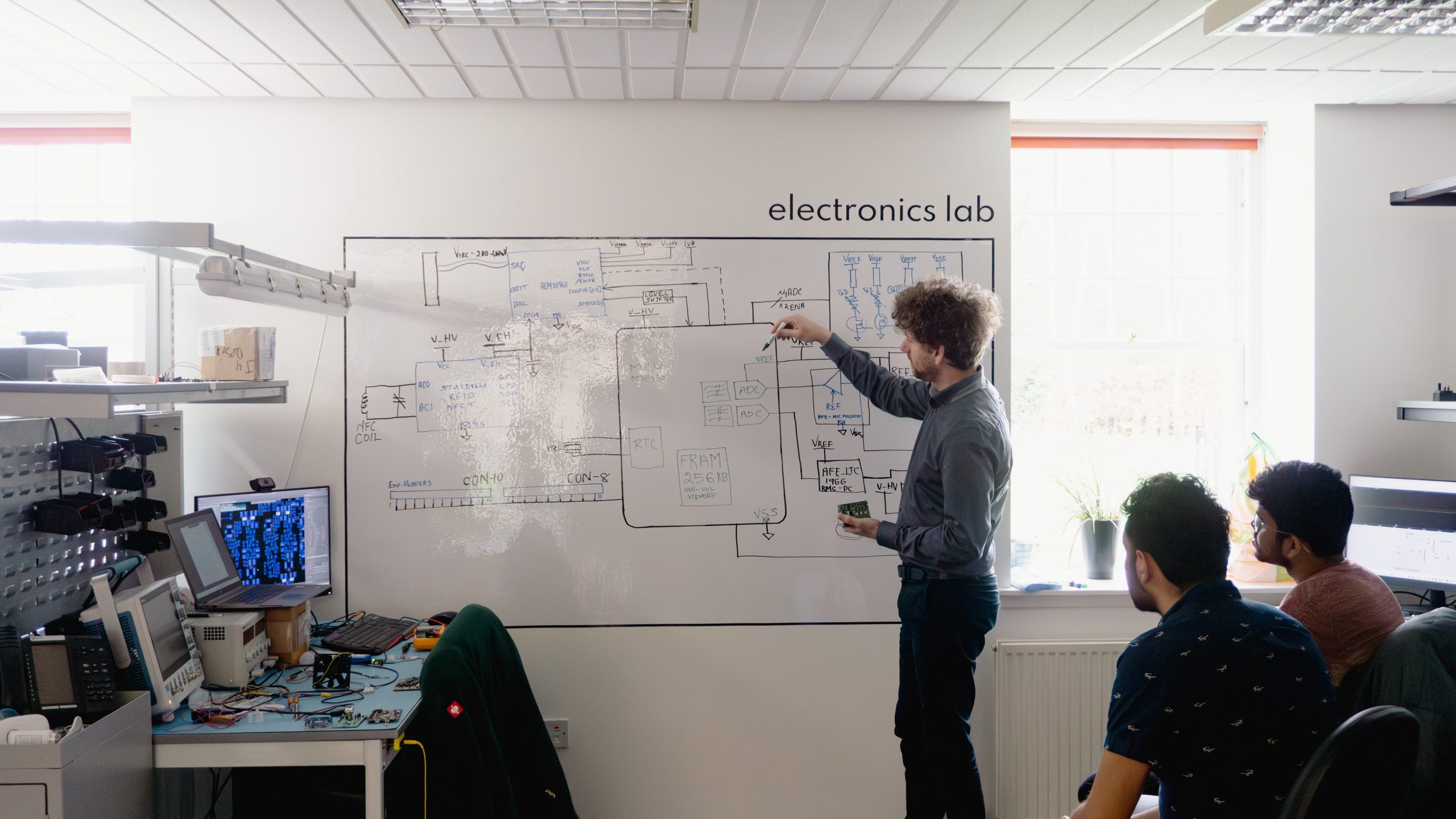

Our team worked with novosound under a retainer agreement to support the development of electronics and software across multiple of their sensing platforms. These have covered an array of requirements for Novosound’s clients, ranging from wearables to systems for hazardous environments. The goal has always been to deliver reliable, manufacturable hardware that can be adapted across use cases and deployed quickly.

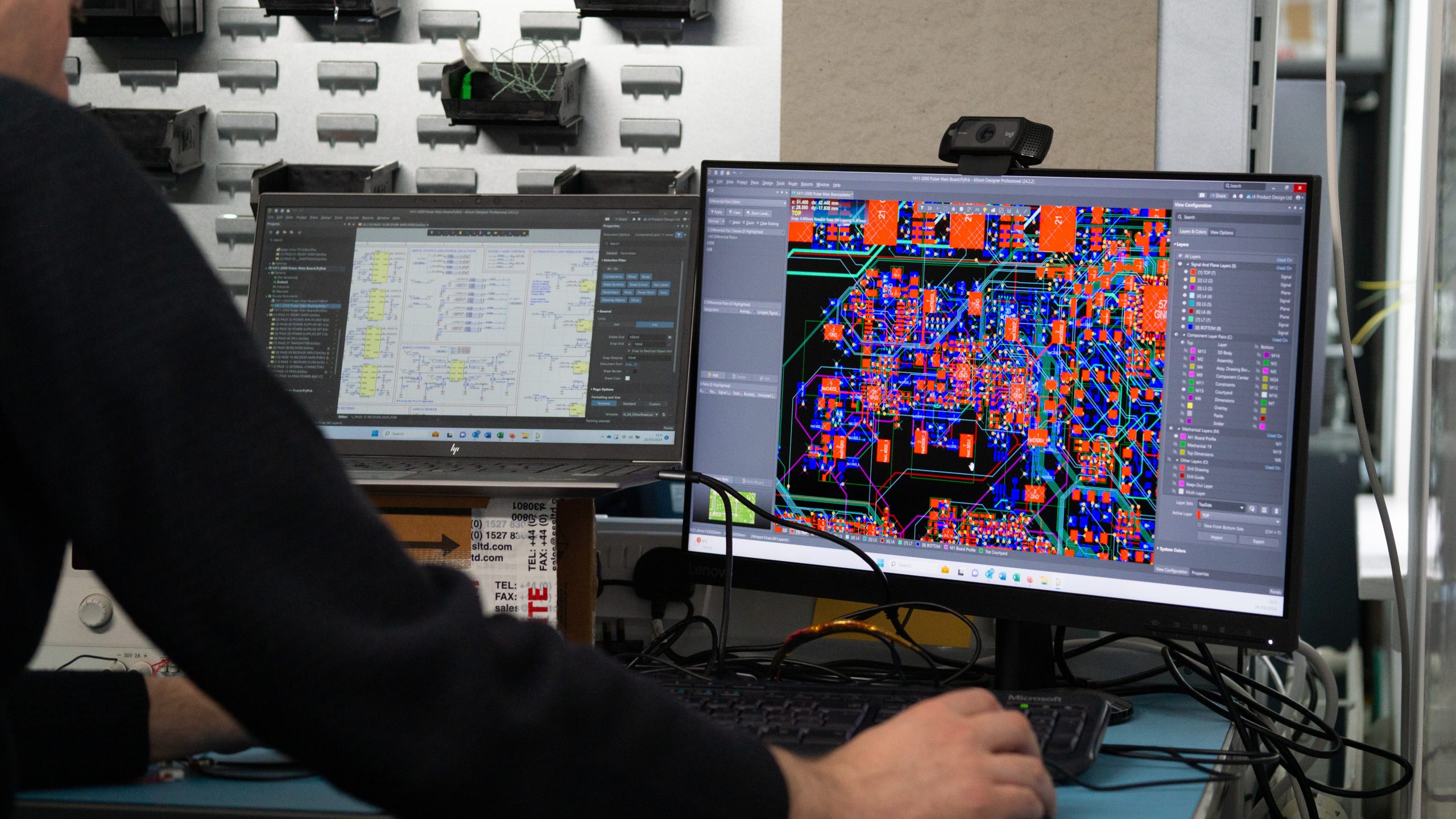

i4PD provided electronics design and software development for two of novosound’s core platforms: Pulsar 4:32 and Pulsar 16:16. The Pulsar 4:32 was developed as a multi-purpose board, capable of serving both industrial and wearable applications. It featured a compact layout, high-speed signal handling, and low-noise receiver circuitry to improve data quality. The 16:16 variant followed, designed for novosound's client that focused on pipe integrity. It was built on this architecture of the 4:32 with improved timing control between transmit and receive modes.

For each board, our electronics and software teams worked closely with Novosound to understand system-level constraints and select appropriate components. We added debug features to aid development and increase speed, and tailored the PCB design to be optimised with manufacturer capabilities.

A third project, Ceilidh, required a complex board layout phase to to ensure suitability for hazardous environments and operation on low-power battery systems.

The projects often ran in parallel, requiring an agile approach from our project management team. They worked between our in-house engineers and clients to uphold rapid communication through shared Teams channels and weekly meetings. This structure allowed solutions for component availability issues, which were quickly communicated and resolved through redesigns, and signal integrity challenges which were addressed through careful layout and timing adjustments. Our structure allowed novosound to move forward and stay informed without needing to expand their internal team.

i4PD have delivered electronics and software solutions that have enabled novosound to support multiple client applications from a shared hardware base.

The Pulsar boards gained significant improvements in receiver performance and signal clarity and the Ceilidh platform showcases excellent low-power efficiency. i4PD have also augmented mechanical design aspects of another novosound medical project.

These outcomes helped novosound meet demanding client requirements while maintaining speed and flexibility in their own development process.