Cytomos approached i4PD with the challenge of taking their cytometry technology to the next stage of prototype development, ready for commercial and collaborative engagement. Initially focused on refining an existing enclosure, the project quickly evolved into a sprint prototype redesign. Work commenced in September 2023 and a demonstrable, redesigned prototype device was delivered by Christmas that year.

Cytomos is a biotechnology company developing advanced cytometry technology. Their core innovation is a chip-based sensor system that uses electromagnetic fields to detect and identify substances based on their unique electromagnetic “fingerprints.” Unlike traditional laser cytometry, Cytomos’ approach eliminates the need for chemical markers, offering a more flexible and efficient solution for substance identification

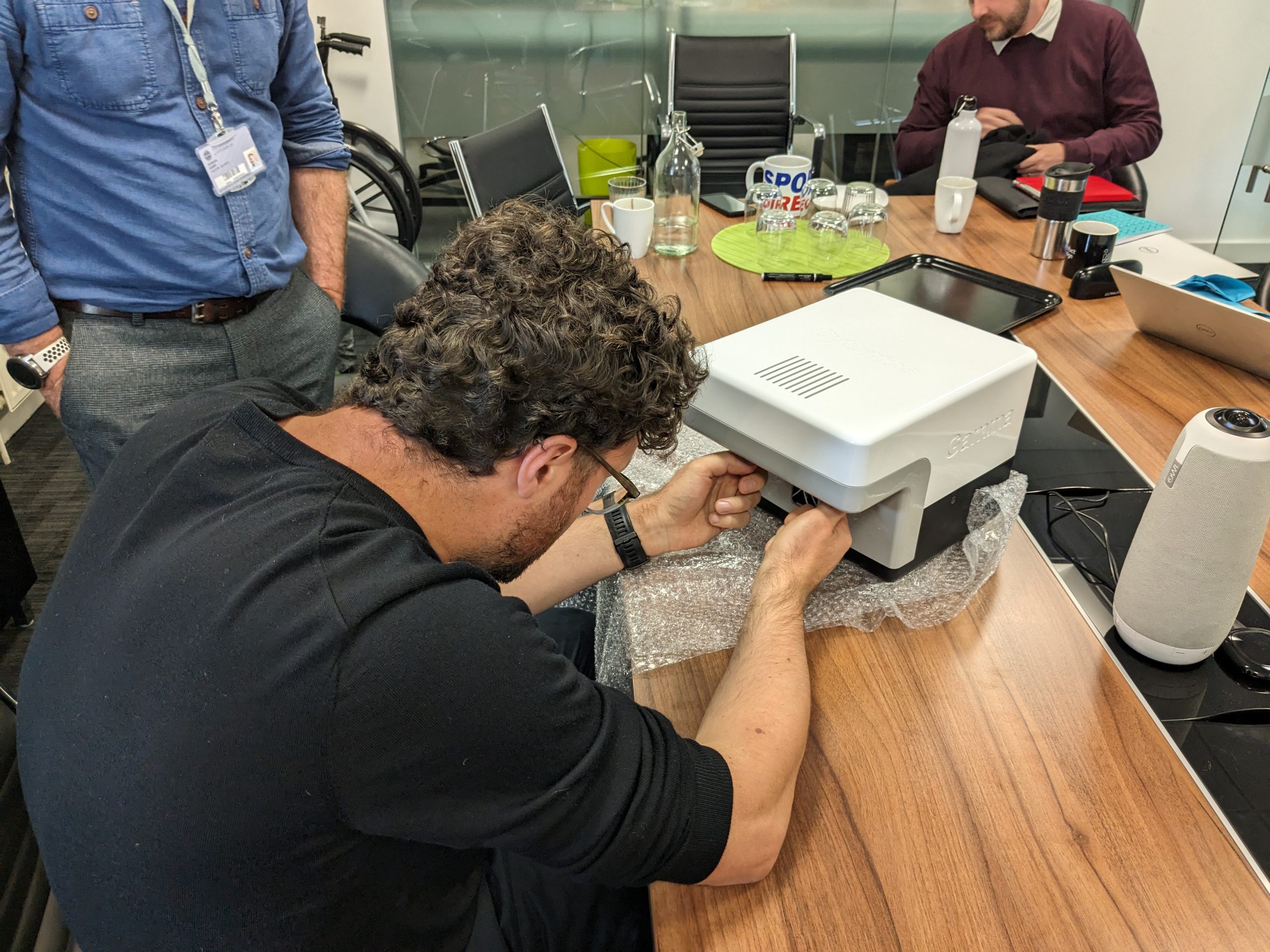

Cytomos approached i4PD with a partially functioning prototype that had been in development for several years.

They needed a fully integrated, user-friendly system to demonstrate to stakeholders within just 4 months.

The existing prototype had functional limitations, including fluid leakage risks and struggles with usability.

Cytomos required support in mechanical design, industrial design, and regulatory compliance to arrive at a testable and certifiable prototype.

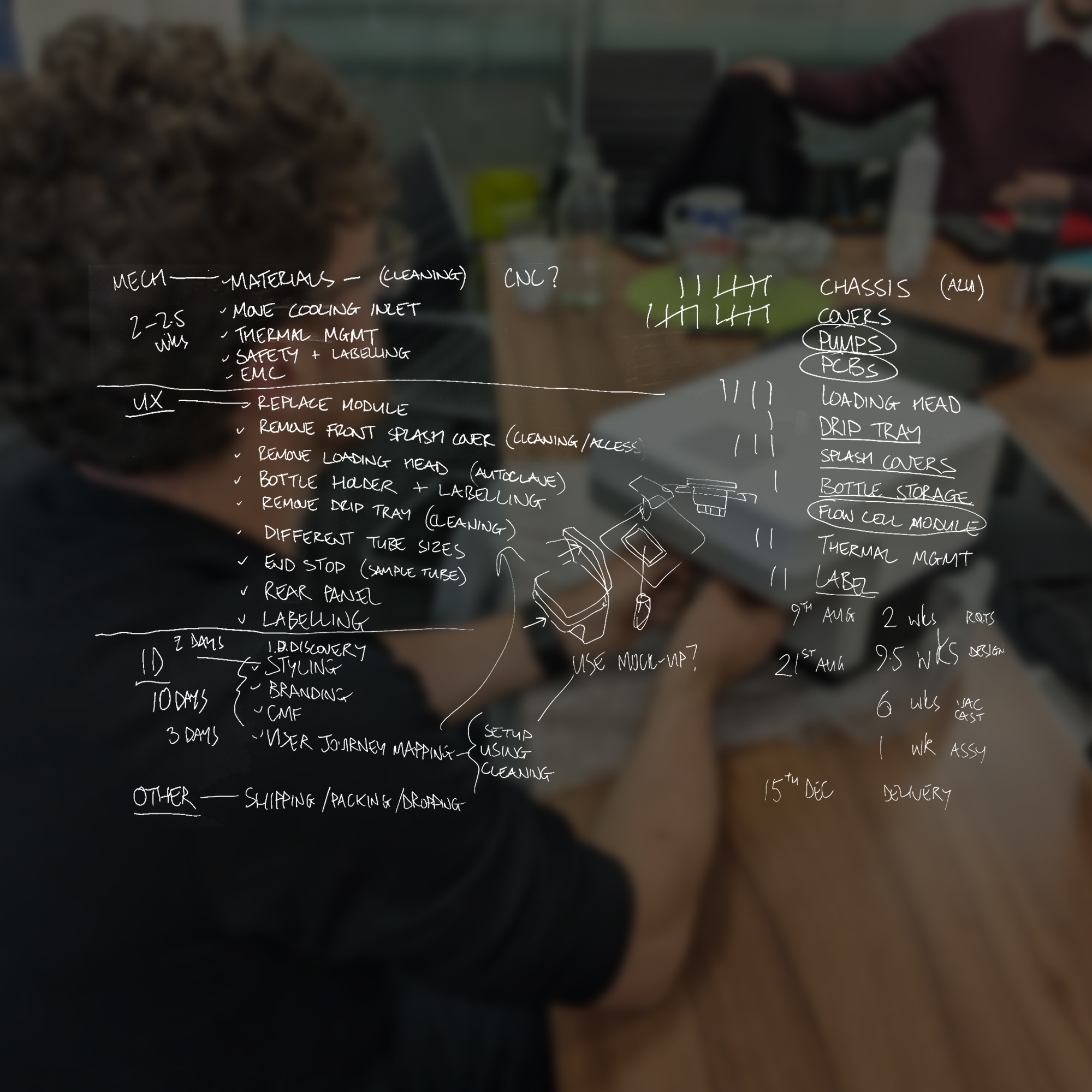

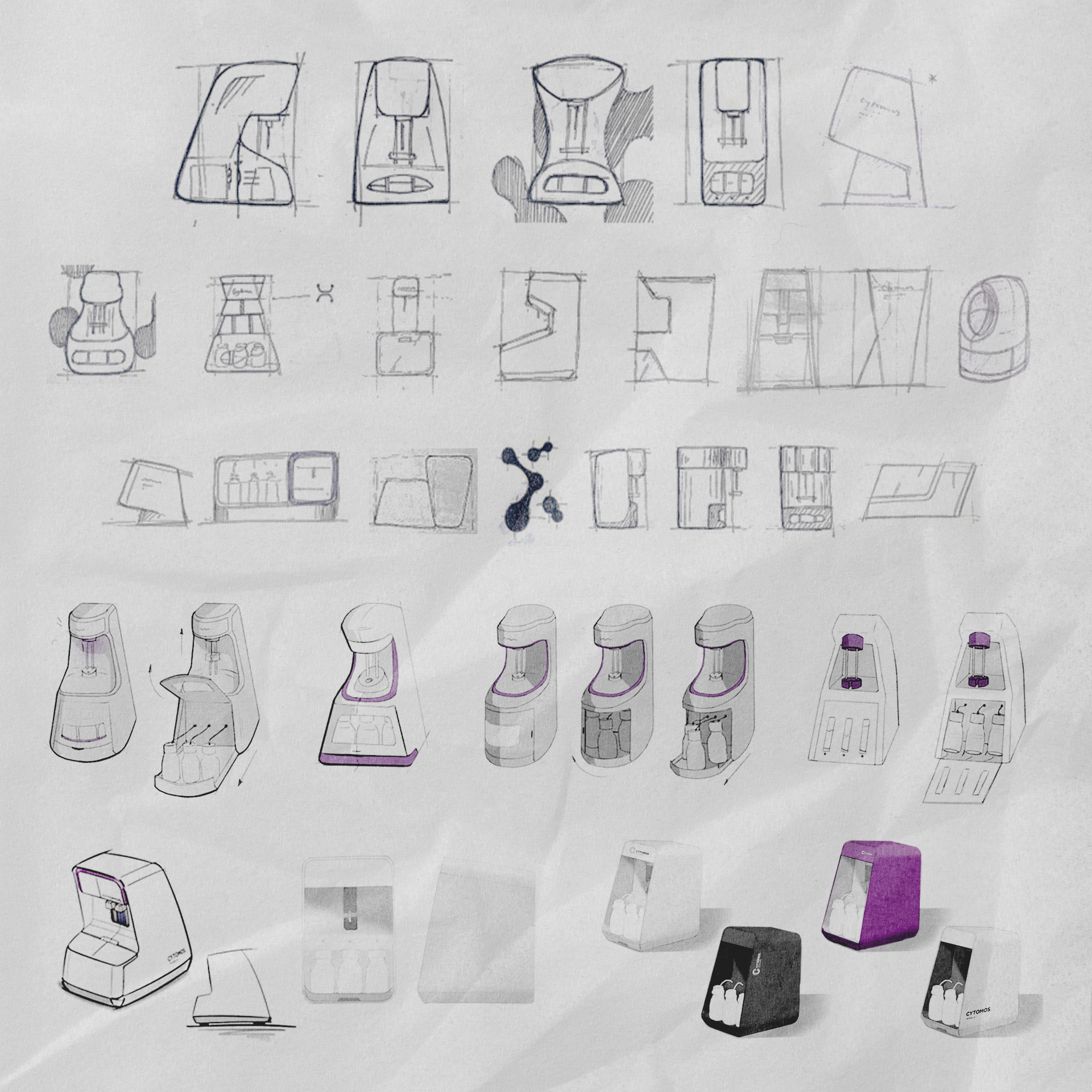

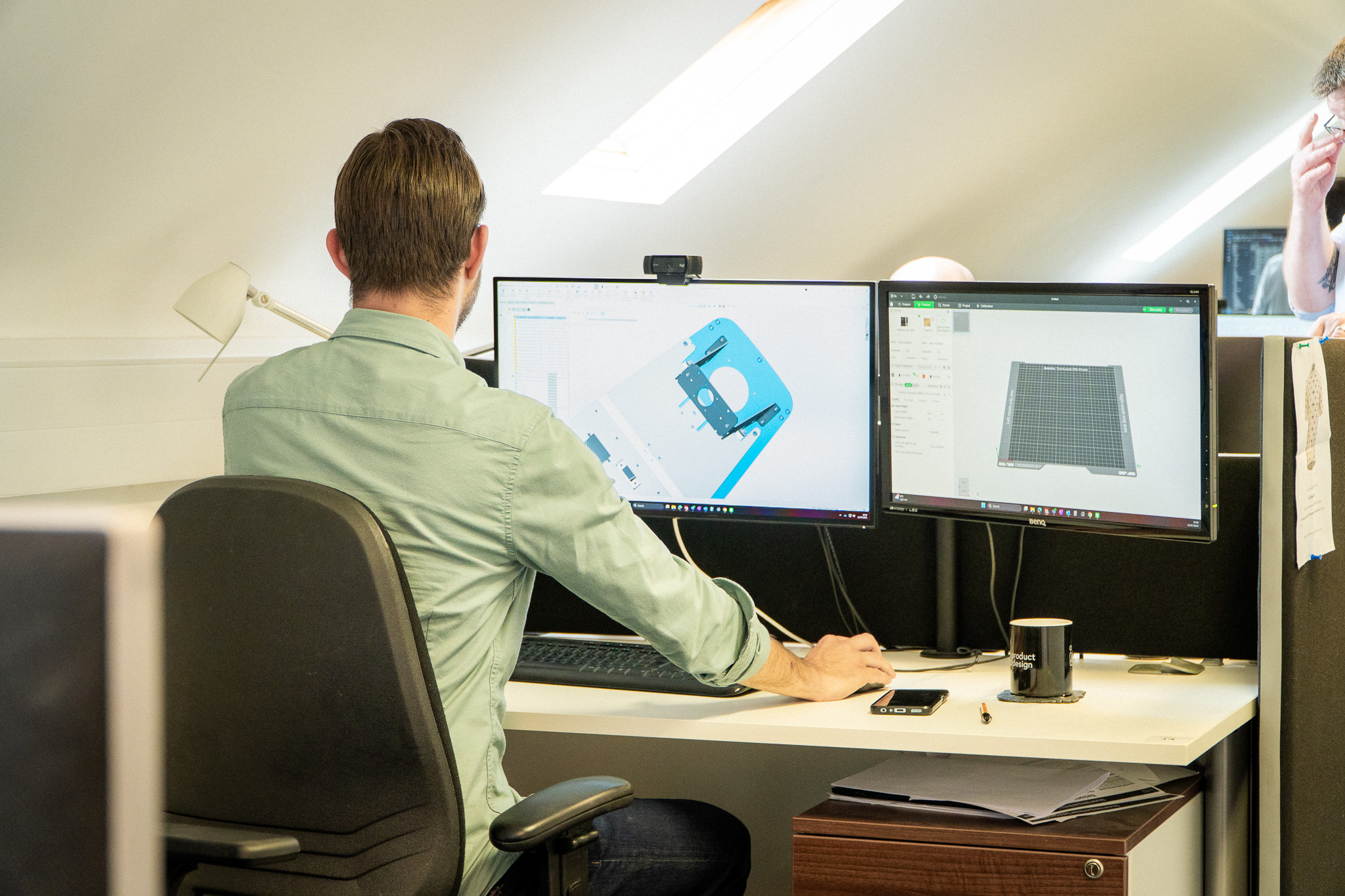

To meet the ambitious timeline we'd been challenged with, our industrial and mechanical design teams mapped out a fast-tracked, parallel working approach to redesign and order the parts required in a focused 10-week sprint. The internal architecture was re-engineered from the ground up to protect sensitive electronics from fluid exposure. Our teams also developed and styled robust new chassis and outer enclosure to improve modularity, usability, and appearance.

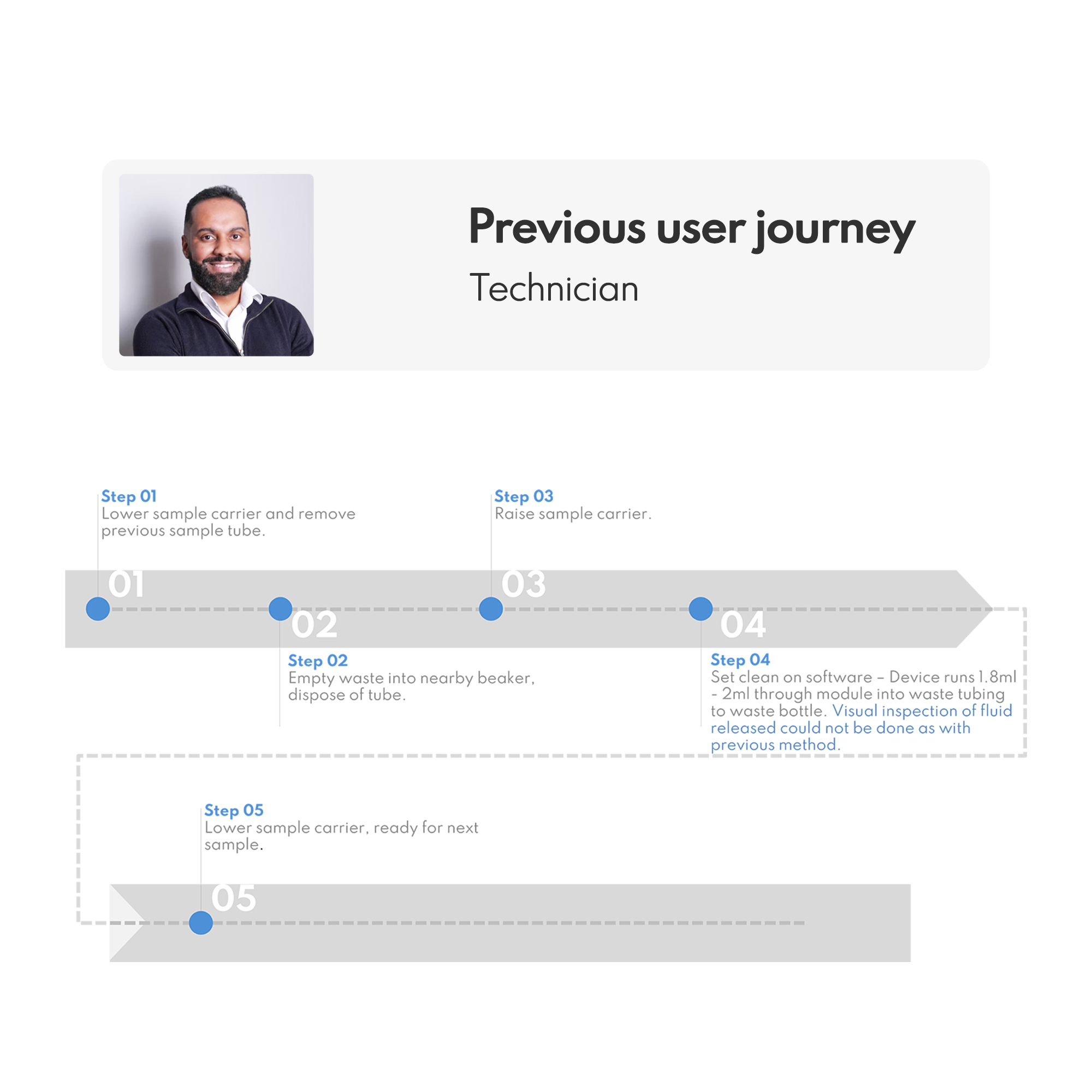

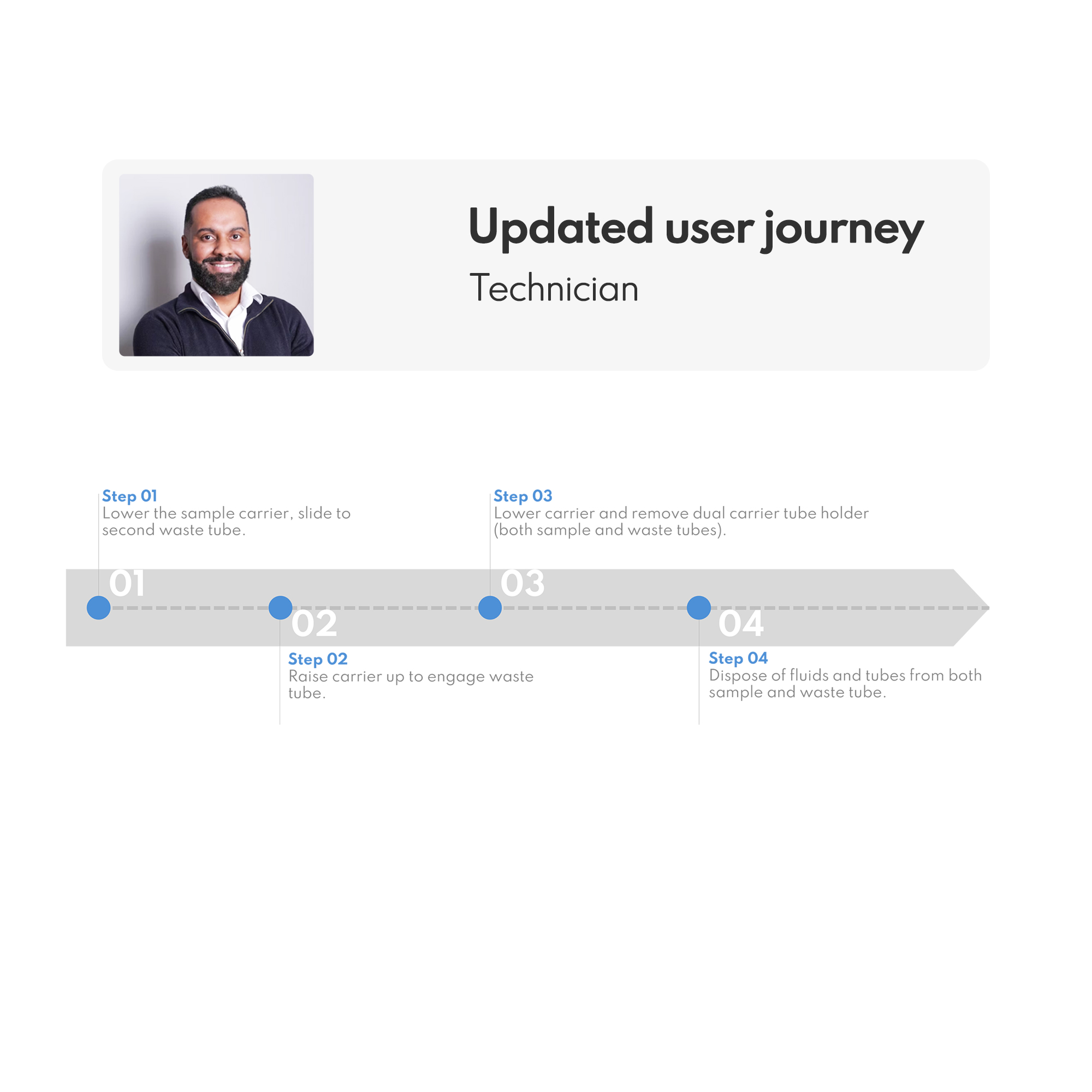

Before any design work took place workshops were conducted to understand the user journey of the current prototype, and plan what the desired outcomes would be for the i4PD redesign.

Collaboration (as always) was the key pillar for the rapid acceleration of this project. Our design engineers worked closely with Cytomos and their preferred U.S. based supplier to integrate a complex yet user friendly sample loading mechanism. Workshop prototyping ensured that the design was intuitive to use without compromising on functionality. Our in-house regulatory team were focused on requirements from day one, helping the design and engineering teams to create a test-ready prototype that could be confidently used in external evaluations.

Delivered within just 12 weeks, the Cytomos Celledonia prototype demonstrated quality industrial design and mechanical engineering at pace. The final Cytomos prototypes featured a chassis made from custom sheet metal and CNC parts, and a clean, styled enclosure made from vacuum casted plastics with a user-friendly layout optimised for market testing. Following this successful project delivery, i4PD continued to support Cytomos throughout the following year. Our teams refined the design, assisted with regulatory compliance, and implemented improvements to the prototype based on product testing and user feedback.