How can mechanical design and engineering replace the role of a physio in spinal therapy? i4PD’s collaboration with Pacla Medical for the design of BackHug resulted in a robust, manufacturable, and clinically effective device now in use across the UK and US.

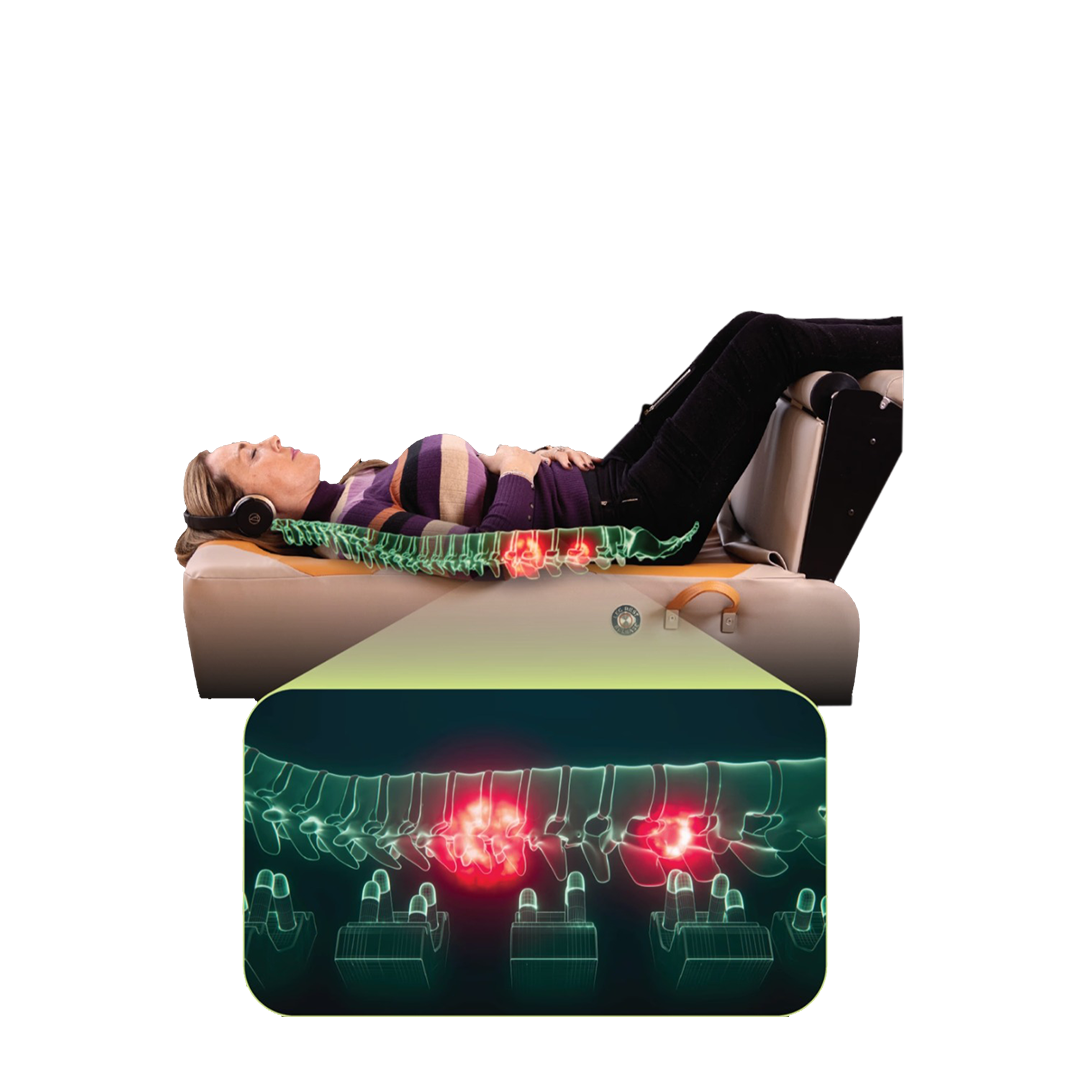

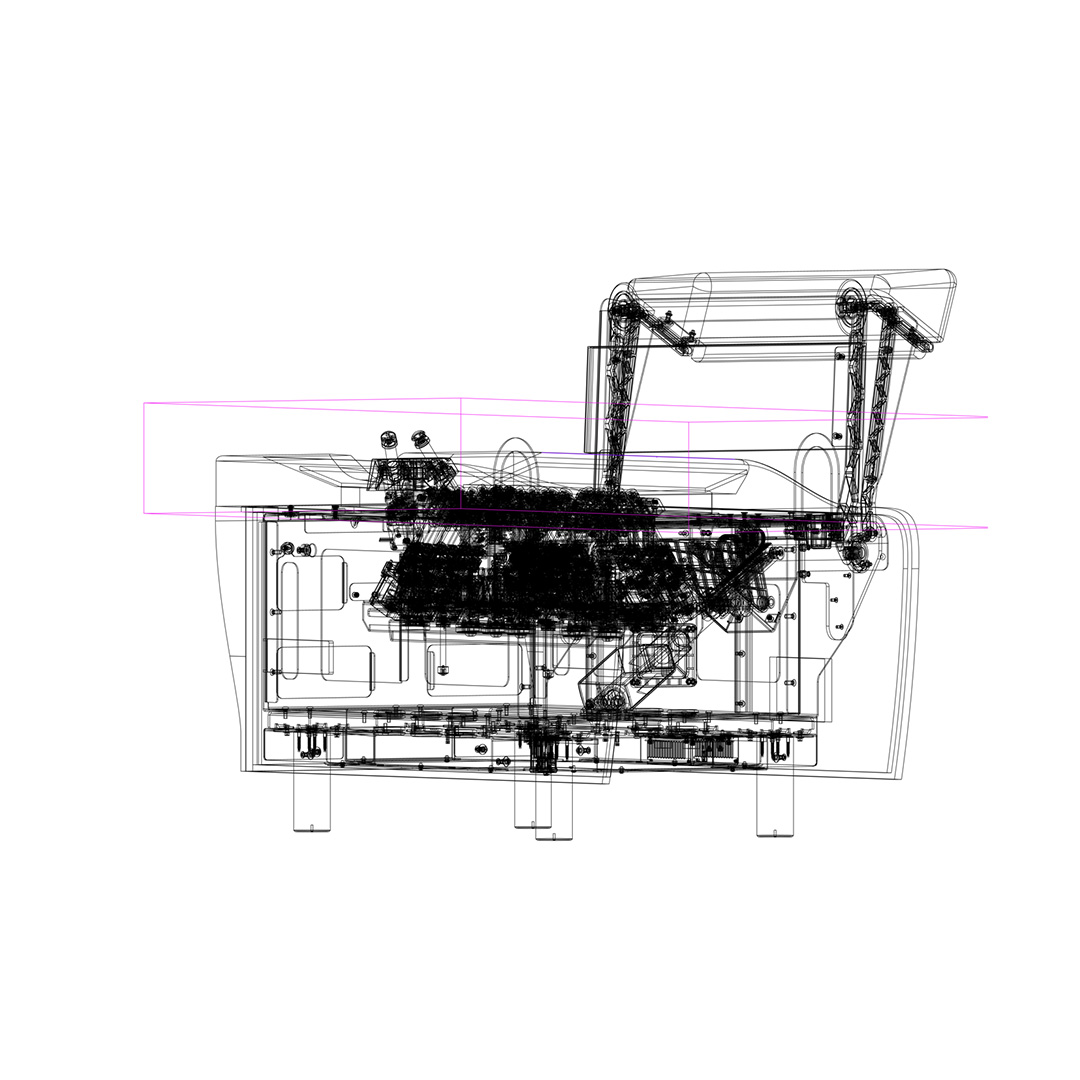

Pacla Medical is a company focused on delivering a solution to back pain through their flagship product, BackHug, a robotic therapy system designed to replicate the techniques of professional physiotherapists. Using 26 precision engineered robotic fingers, it scans and treats the user’s back, targeting stiff joints and tension areas.

Pacla’s vision for their next generation product was ambitious. Their early prototype was a great proof of concept, however, there were areas that needed refinement to make the product more effective and comfortable. The Pacla team had ambitious goals in mechanics, assembly, and ‘therapeutic effectiveness’ but lacked the internal time and resources required to meet their targets.

The company needed a partner who could:

i4PD began a re-design of the machine on a clean slate, working closely with Pacla to reimagine the product. The collaboration has spanned several years, through multiple iterations. Each iteration a response to clinical insights and patented engineering innovations.

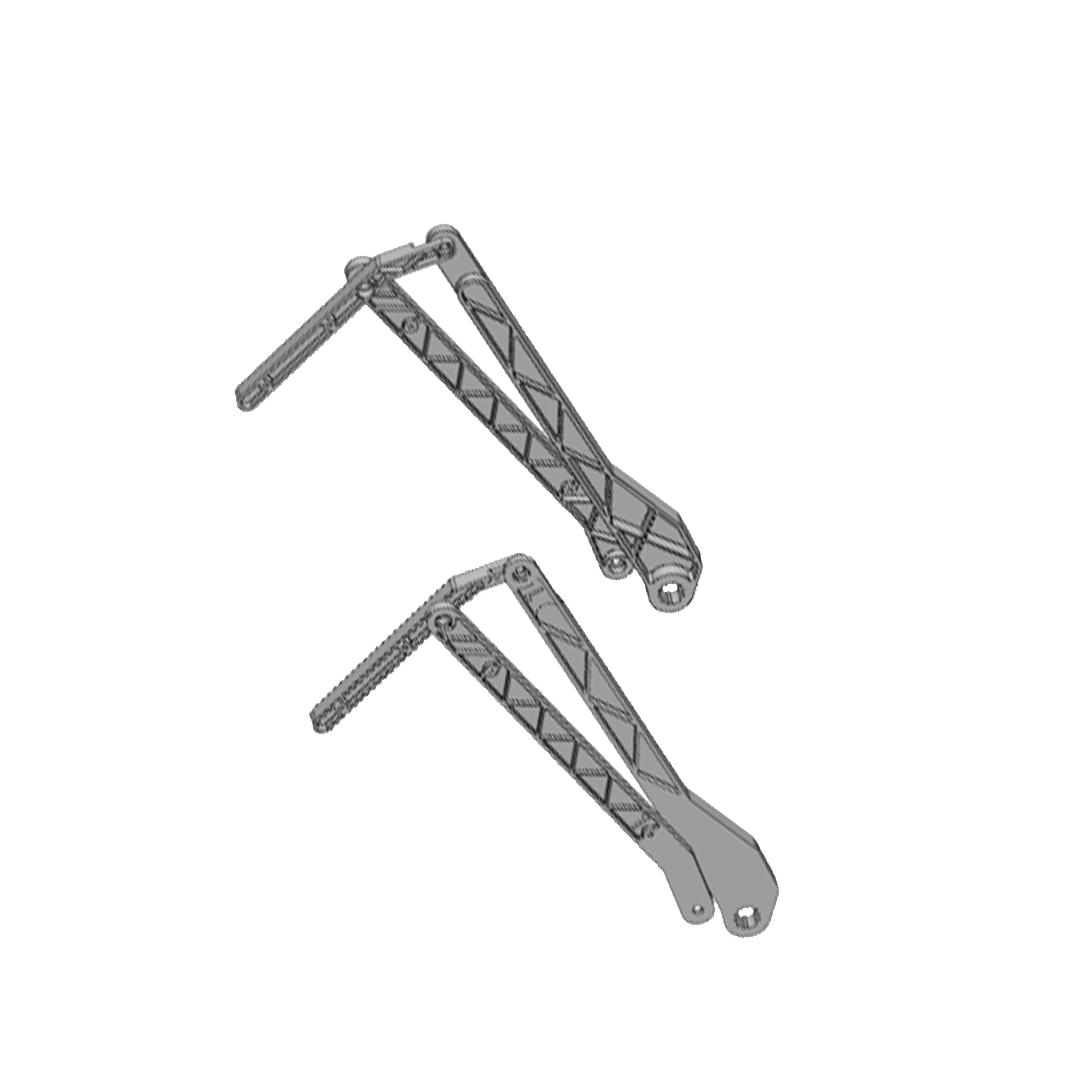

1. Compact Multi-Linkage Leg Rest.

One of the most technically challenging and impactful innovations was the redesign of the elevated leg rest. The original system relied on stacked cushions and failed to elevate the legs effectively. Our mechanical engineering team developed a clever multi-linkage mechanism using a simple actuator and rack-and-pinion system. This system allowed the leg rest to fold away into the unit while achieving the necessary elevation for effective therapy when folded out (a critical factor in patient outcomes).

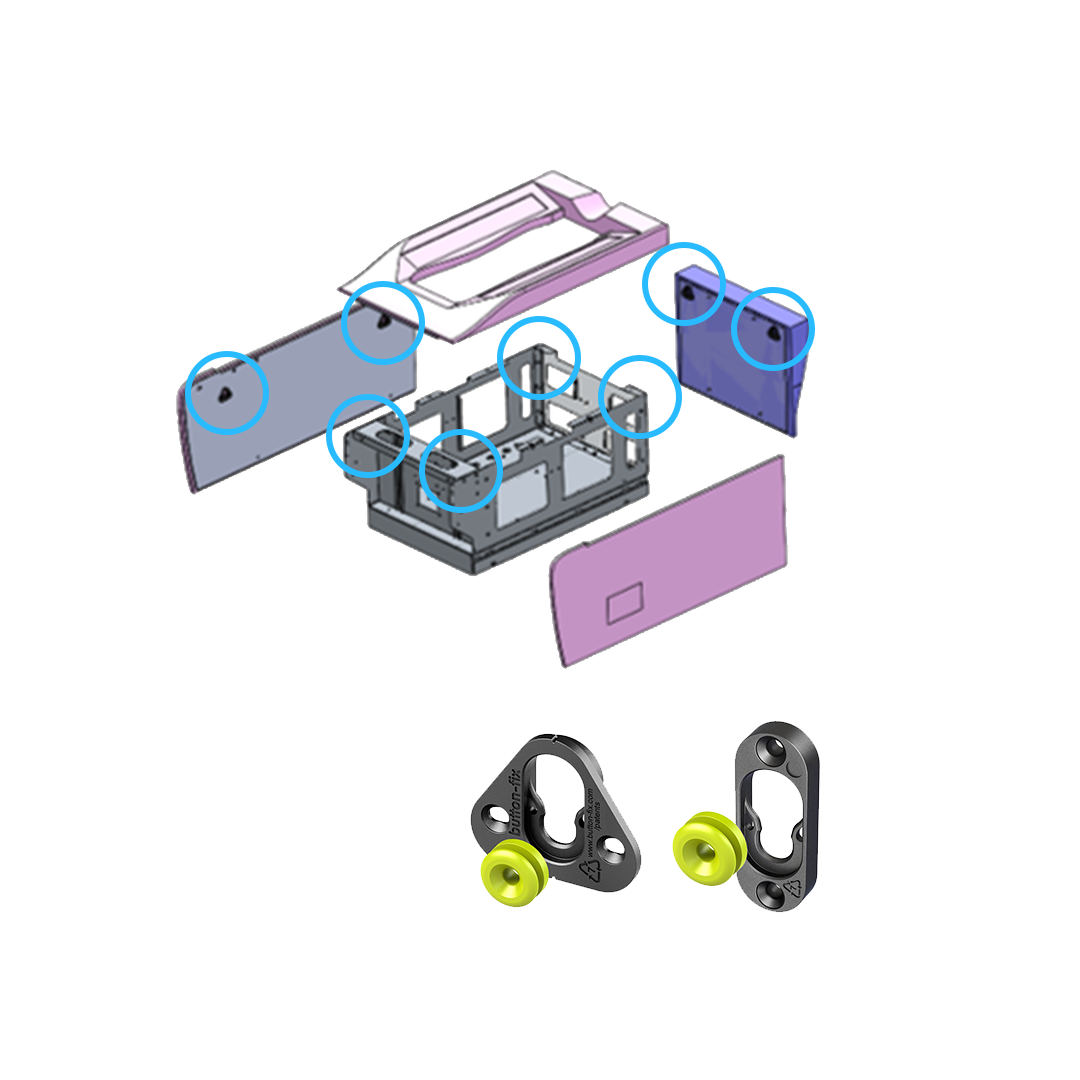

2. Flat-Pack Upholstery System.

To address shipping inefficiencies, i4PD introduced a modular upholstery system using button-fix panels. This allowed the product to be shipped flat and assembled on-site, significantly reducing logistics costs and increasing the number of units that could be transported at once. Additionally, it also simplified maintenance and replacement of parts, improving the product lifecycle.

Throughout the projects, i4PD maintained a highly collaborative and communicative relationship with Pacla. The team worked closely with the company’s founder over multiple projects, responding to evolving clinical requirements and testing feedback.

“We found the team to be comprised of experienced, high-quality engineers who could tackle any challenge we presented. Even when specific issues initially seemed daunting and difficult to address, the team consistently found ways to resolve them, often by developing innovative solutions.

What stood out was their multi-layered engineering revision and quality control process. This ensured that every piece of engineering work, big or small, was thoroughly reviewed by the team before finalisation”

ChongSu Lee, Founder & CEO

The latest BackHug production model includes:

The device delivers deep tissue therapy comparable to a professional sports massage. A mobile app supports Pacla’s control system, which allows the user to specify adjustable intensity and targeted treatment zones.