Novosound's pioneering thin film deposition method for generating flexible ultrasound arrays is set to shake up the Non-destructive Test (NDT) market which is dominated with manufacturers of piezocomposite, piezoceramic or single crystal materials which have drawbacks from a production cost and performance perspective.

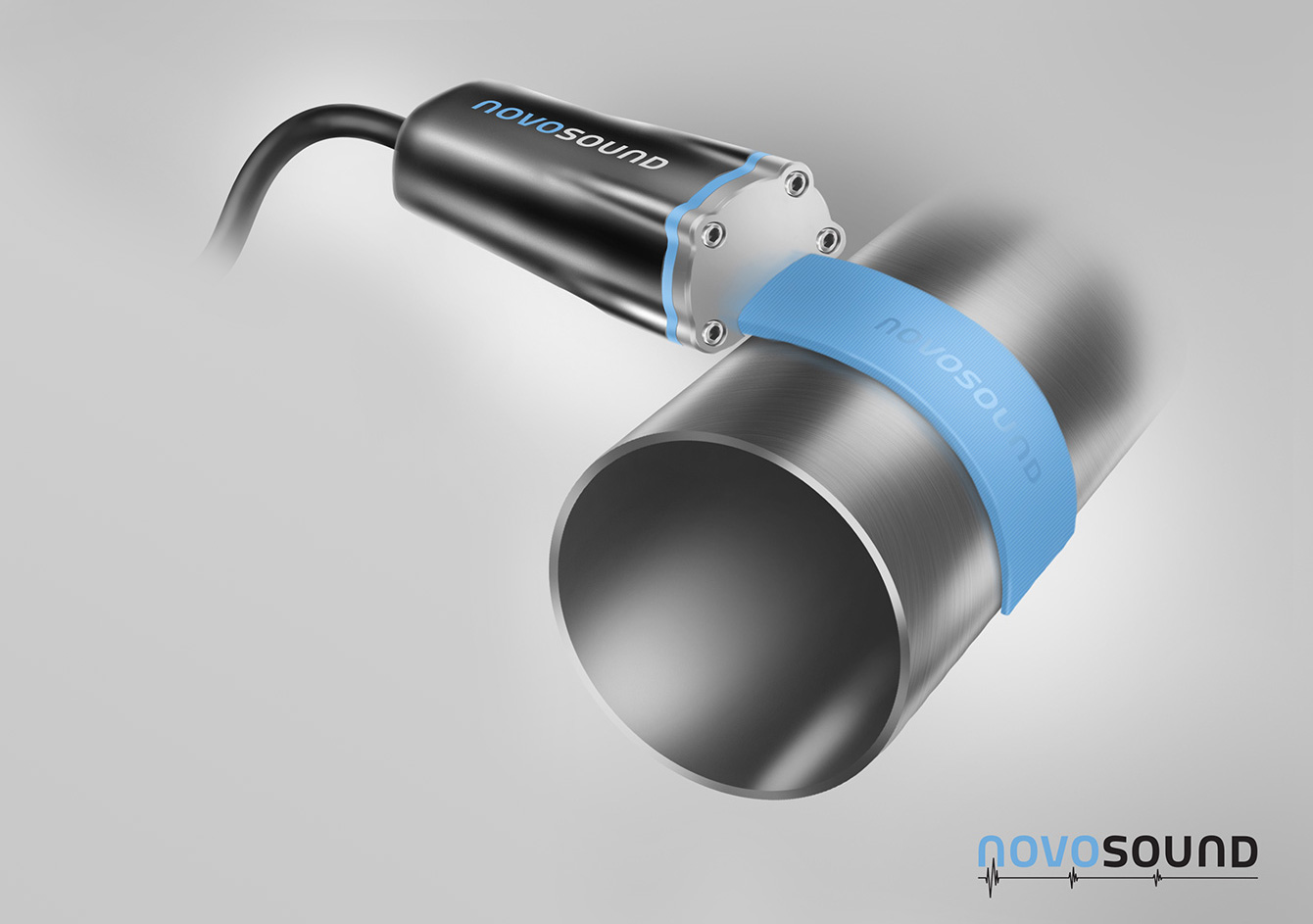

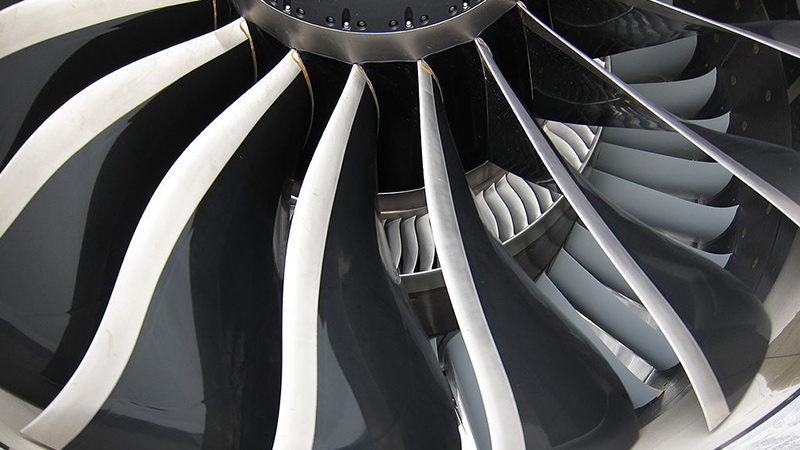

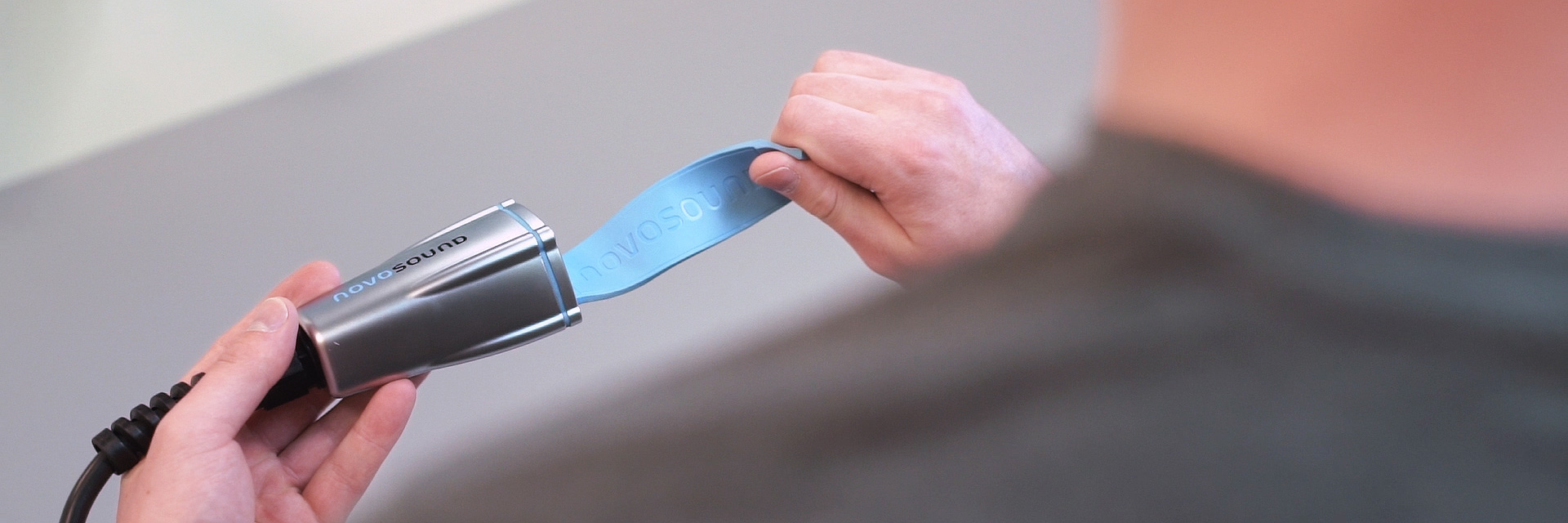

Novosound approached the i4pd industrial design and engineering team to design a rugged, ingress protected enclosure to house the probe's electronics and address the challenge of holding/protecting their flexible array for NDT applications - specifically on complex/curved surfaces. The company wanted to showcase an appearance model at the upcoming industry show in the US.

The engineering team led the development by looking at ways to generate a low-cost manufacturable solution for encapsulating the flexible array without damaging its surface in the process. An overmoulding process was settled upon which would also offer encapsulation of the array but also act as a gasket for the electronics housing.

The product was showcased at the trade show to great acclaim and the company has since secured significant orders and continued investment to support the development of future products.

We like to find new, better and efficient ways of doing things. Contact us to discover how i4 Product Design can solve your current design challenge and take your product to the next level.

Copyright © 2024 i4 Product Design Ltd. All rights reserved. | Privacy Policy